OUR PRODUCTS

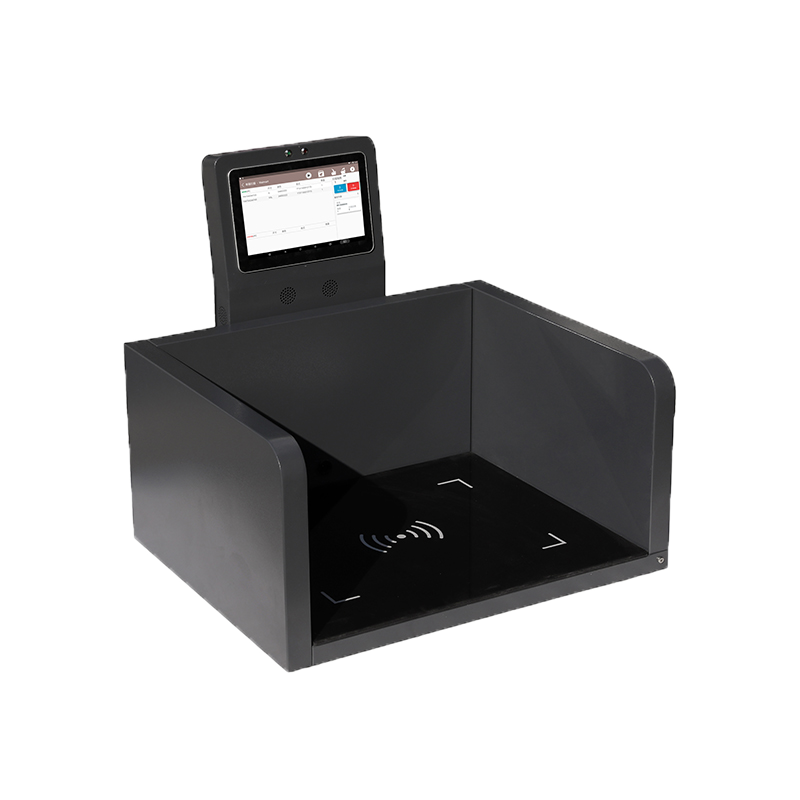

- High identification efficiency: It only costs 3-5 seconds to read 200+pcs of tags.

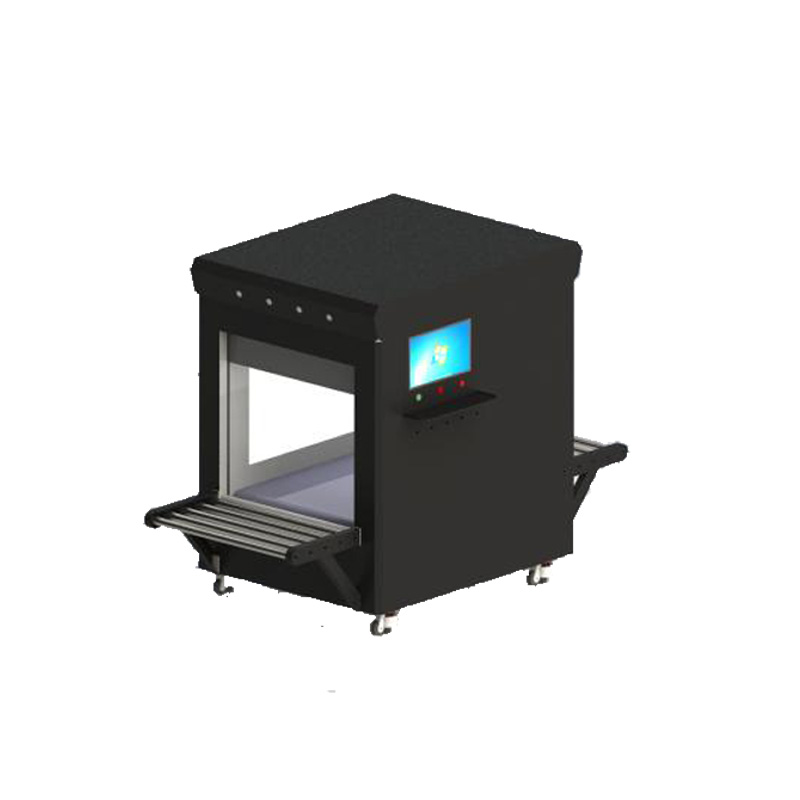

- Professional motion control and mechanical design fully solves the problem of tag miss-reading;

- Compact electromagnetic shielding and radio frequency optimization can eliminate the harm of RF radiation to the human body, and the tag reading accuracy reaches 100% (Depends on the reading environment and performance of tags);

- The industrial computer software can control the function of the whole machine and monitor the running status. There are also external mechanical buttons, which are convenient for the operators to control the working status of the equipment at any time;

- The design of industrial belt conveyor fully solves the belt offset maintenance problem;

- There is access door on both sides, which facilitates the equipment maintenance;

- Optional sorting module for abnormal boxes/goods/items meets the needs of different users. And we support customers to develop secondary software.